PC_BULLET_EMPIRE

25 Jan 2019

Let's look at the 350 Legend

1

0

838 Views

In General

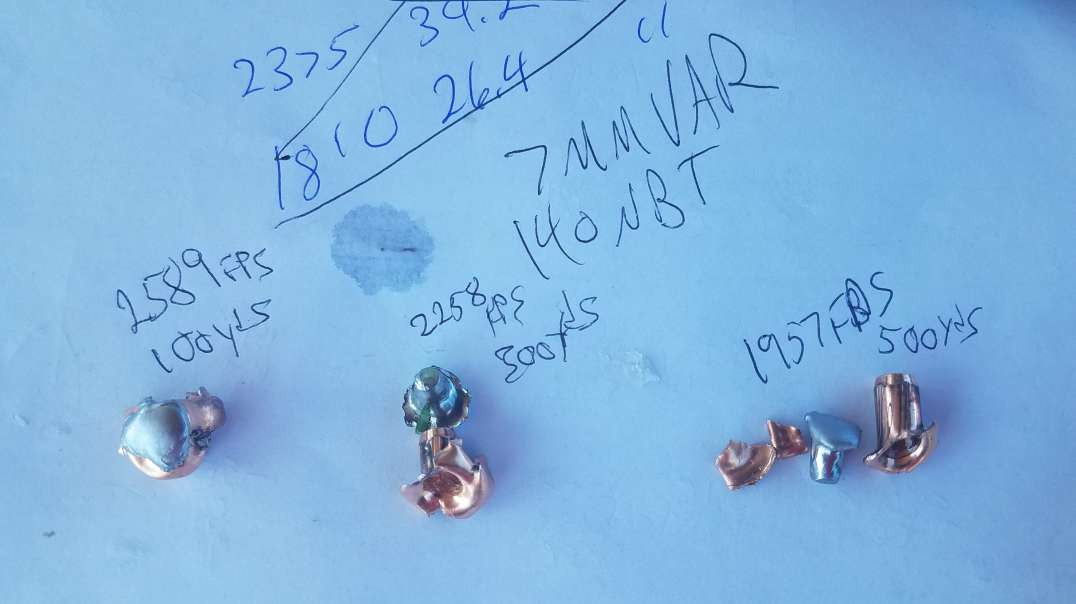

My attempts to duplicate the 350 Winchester legend

Show more

Two things:

#1 = The cartridge headspaces on the mouth of the case, just like a 9mm or other straight walled pistol cartridge (380, 45, 40, 10mm, etc . . .) roll crimps like formed by 357-mag/max dies should not be used. A 9mm crimp die backed way off may work. You need a very gentle taper crimp, and not in a crimp groove but rather crimping in the center of a driving band on the bullet. Just like done when loading 9mm, 380, 45, 40, 10mm, etc . . . The wildcat cartridges "357-mag Rimless AR" and "357-max Rimless AR", the later of which is a "kissing cousin" to the new 350-Legend the guys who load those wildcats use a very gentle crimp and do not crimp in crimp grooves but on a full diameter part of the bullet Various means are used to do such a crimp. Best method I have heard of is using a 32-40 sizing die with the center decapping and neck expansion pin removed and screwing it into the press just far enough for the body taper portion of the sizing die to gently taper crimp the mouth of the case.

#2 = The new 350-Legend is not a true straight wall case design. From close analysis of the pictures Winchester has on their website. The case does have a very slight taper to it. The case head forward of the rim (which is a standard diameter 223 rim) has been slightly increased in diameter. Exactly how much is unknown, my estimates from pixel count measuring of the best picture Winchester has on their website estimates a case head diameter of about 0.390" forward of the extraction groove if it is assumed the rim measures exactly 0.378" same as standard 223. You can see my analysis on a reloading forum here: http://forums.handloads.com/fo....rum_posts.asp?TID=36

I am not so sure that the case will balloon out to that larger diameter at the very thickest and strongest part of the case head without completely annealing the entire case including the head, which would severely compromise the case heads strength unless quench hardened after the fire forming process. And then you would be relying on your skill in that quench hardening process to restore case head strength sufficiently for full power loads from then on. Something I am not so sure I would be confident in my own abilities for to that extent.

Your mileage may vary. I really liked watching your video and your on the right track if you wanted to make the "357-max Rimless AR" wildcat just need to change your crimping method. Not so sure you can go to 350-Legend spec. cases straight from 223 though due to the head diameter expansion they did in the design to allow for a small amount of taper in their cartridge design. Which in and of itself is a good idea. Extraction has been a reported issue with the perfectly straight sides of the wildcat cartridges I have mentioned and adding in a little taper like they seem to have done is a good solution. Just makes it more difficult for the average Joe to try to make cases to that spec. on our own starting with 223 brass or even starline 223 "basic" brass.