IvanTheTroll

02 Jun 2019

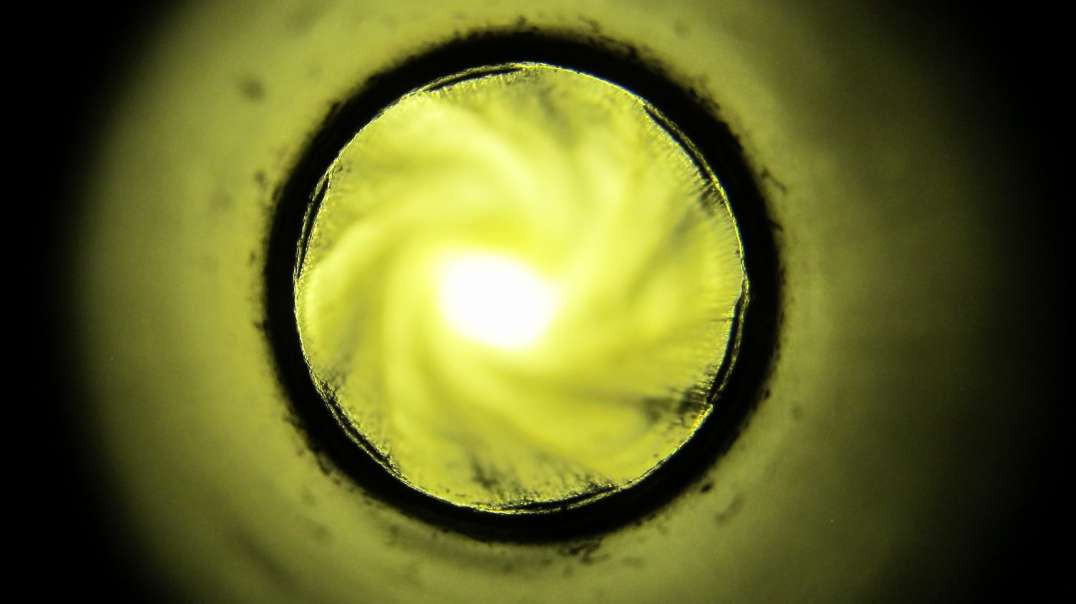

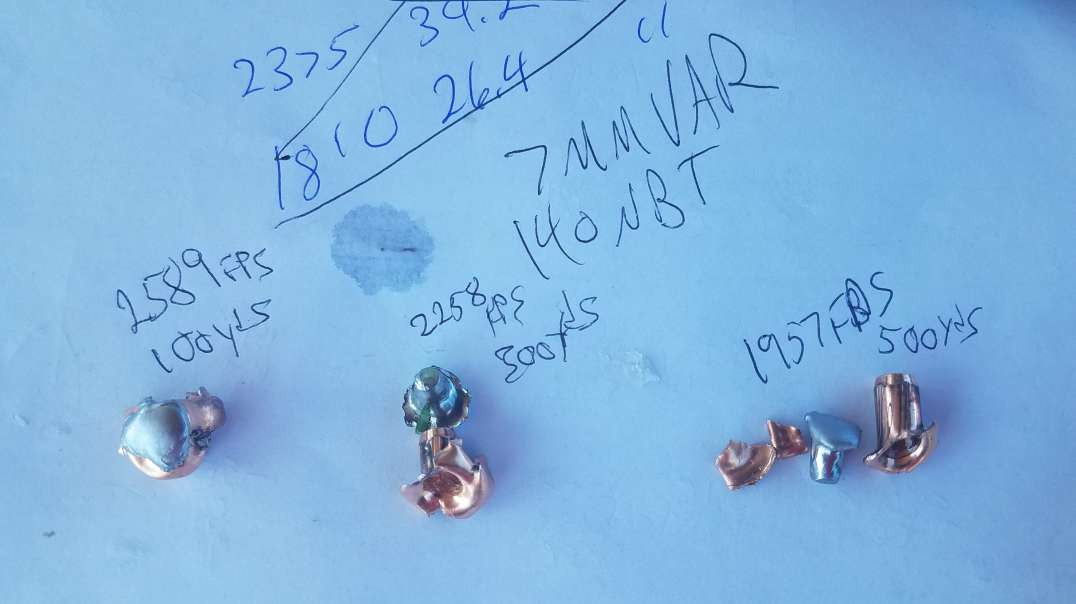

How to use ECM to rifle a barrel - DIY barrel rifling - Project ButWhatAbout

53

2

419555 Views

In General

This video is no longer playing correctly on this site. You can watch a mirror of the video here: https://lbry.tv/@Ivan's_CAD_Streams:c/ECM-Barrel-Explaination:e

In this video, I touch on all the components of my rifling setup. Between this video (the most important part of the tutorial), and the tech writeup (linked below), other folks (it could be you!) can replicate my results.

Complete ECM DIY Barrel Package + Tutorial:

https://lbry.tv/$/download/Pro....ject-ButWhatAbout-EC

email me: [email protected]

Keybase: IvanTheTroll

Show more

Could you share a pdf explaining how you make the cutting solution and power the electrolysis process, please? Also, is there someone from whom I could buy the CNC printed parts? You maybe? I don’t want to learn CNC printing to make a barrel. Of course, since mine would be a16.5” barrel I presume I’d need a longer rod.

My last month paycheck was for 11000 dollars… All i did was simple online work from comfort at home for 3-4 hours/day that I got from this agency I discovered over the internet and they paid me for it 95 bucks every hour…..> https://www.pay.salary49.com

Im making over $28k a month working part time. I kept hearing other people tell me how much money they can make online so I decided to look into it. Well, p it was all true and has totally changed my life. This is what I do.

AND GOOD LUCK.:)

HERE====)> https://www.salarybiz.com

When looking to buy pull-out couches, there are several options to consider. You can check furniture stores such as IKEA, Ashley HomeStore, and Wayfair. Online marketplaces like Amazon and eBay also offer a wide range of choices. Additionally, consider local classifieds, thrift stores, and online classified websites like Craigslist for potential deals.

HERE——➤ https://www.puloutcouch.com

its cute and all but you still pay taxes to corrupt pedophile satanists and fund false wars. sooo keep it up I guess.

We have no other option for change, in my opinion, so we must use force. For more than 45 years, unscrupulous politicians have controlled this nation. Everyone in government who has served in the last 45 years has baggage. They should all be tried and looked into.I work on my homework. https://netpayfast.com/

I make $100h while I'm traveling the world. Last week I worked by my laptop in Rome, Monti Carlo and finally Paris…This week I'm back in the USA. All I do are easy tasks from this one cool site. check it out,

:) AND GOOD LUCK.:)

HERE====)> https://www.apprichs.com

My last month check was for 11000 dollars... Everything I did was basic online work from comfort at home for 3-4 hours/day that I got from this office I found over the web and they paid me for it 95 bucks each hour... Attempt it yourself....

:) AND GOOD LUCK.:)

HERE====)> https://Www.Worksclick.Com

I just got a military grade laser sight just released to the public I love it. Check it out here https://bit.ly/3r8sadS

Video is broken; mirror: http://web.archive.org/web/202....00426232832/https://

What's wrong with this video? It seems to be corrupted or something.

Mirror to this video?

The video isn’t here

Very interested in this method. Any ideas on using 3D printing to produce the "tools" with ECM process to produce usable fire control parts. If the bolt faces and firing pin holes can be cut what about feed ribs? What would the 3D printed "tools" be shaped like?

Just a thought, can you use a spent shell cartridge as a chamber boring tool? My idea is to drill a hole through the case insert a metal rod, insulate the rod and use the outside diameter of the cartridge for cutting?

Man I'm impressed as all hell of what you've done here. I've always thought that barrels would be a quite hard wall to crack for any DIY build outside the US since you can't simply order one online. I have not yet tried what you've demonstrated here ( to be fair i just found out about it from the FGC-9 build) however i'm quite interested in trying that. I have a question or two if you don't mind: Does the hydraulic tubing have to be from a certain spec steel? I'm not sure where i'm from i'd find exactly what you have available but with a quick search i could find a seamless tube 16mmOD 8mm ID from" P235TR1 ( 1.0254 ) " steel. Says it's a non-alloy quality steel for seamless tubes for pressure purposes so I'm hoping it'd work just fine. What I'm worried about it the barrel exploding. Do you know if a good number of barrels were made this way and were successful? Again i'm still amazed you didn't need a lathe to achieve this!

Can 6mm 3D printer guide rods be used for boring, chambering etc? According to the description the ones I'm looking to order are 'chromed' - just wondering if that would make a difference compared to just mild steel. Alternatively, can stainless steel be used?

no I can't ,and by the way could I down load the Glock auto sear? and how?

it can not open and download now

It would be great if you could send TheIdahoanShow guy one of your barrels to do a shooting comparison video! His button rifling method is also about this inexpensive and simple so it would come down to accuracy

If I understand correctly you can't use ecm to bore the pilot hole that the rifling mandrel/electrode goes into? (Or it would take forever?) Therefore you have to start with a thick walled hardened tube. If so that limits the types of barrels you can make, no locked breech pistol barrels because those have to start out as billet for all the tilting ramps etc that go under the bore. And I infer that the precision of the pilot hole is important because ecm just erodes equally on the whole surface -it doesn't even out the irregularities in a badly drilled hole it offsets them to a wider diameter.

Does ecm do sharp corners very well? Can you make it so the lands are very thin with sharp edges like a button rifled barred? Is there a conductive uv printer resin that could print an electrode, or could a metal plated 3d printed part be an electrode? Then maybe you could also cut engravings, locking lugs in a slide, other complex cuts with ecm instead of milling? sorry a lot of questions but trying to understand all the practical possibilities of ecm metalwork!

It would be interesting to re-bore and re-rifle an old "shot out" barrel using this method

I'm really impressed but I'm of a slow mind, is there some book you can read on this?

I am impressed, I have been EC Machining for some years now. I find high power constant current PSU's (Buck+/-) the best and most consistent.

If You, like I am sure you do as well, know a bit about Electronics, I am currently busy to integrate whole electric/electronic/mechanical setup like the PSU, pump, pressure, temperature, saline conductivity sensor monitoring using PI/Arduino.

Dasvidaniya ;)

P.S.: Drop me a line if You like.

Do you think it would be beneficial to cut only one groove at a time, then rotate the mandrel? I guess kind of like ram/sinker edm...

Have you tried a stainless barrel yet?

Cool AF! Always thought EDM would make great barrels, never heard of ECM.